-40%

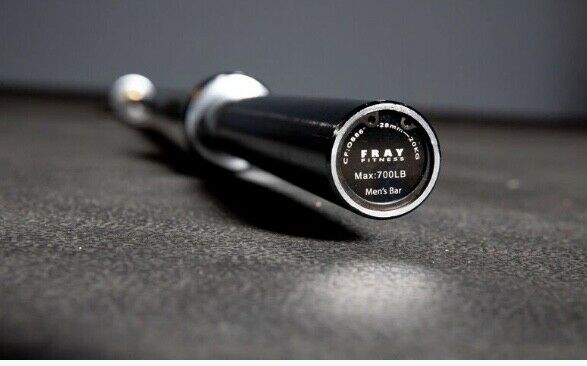

POWER BAR of TEXAS! E-Coat olympic barbell, 7ft, 45lbs hardened chrome IPF IWF

$ 105.59

- Description

- Size Guide

Description

Product OverviewThis is Ripped World's first ever branded barbell called the "Hill Country" barbell. The “Hill Country” barbell is a mid-level barbell for the home or commercial gym environment. It features a long lasting construction design including snap rings, high strength needle bearings and bushings, and a premium coating to prevent common corrosion issues in a sweaty gym!

The Hill Country barbell is geared towards powerlifting exercises but contains IWF, IPF markings, and a center knurling. Why the Hill Country Barbell? The Hill Country barbell is a mid level barbell that is competitively priced at 9.99. Most barbells in this price range offer lower quality finishes that do not protect the barbell against common corrosion issues that arise from gym environments.

The Hill Country barbell exudes a tough surface coating called

e-coat

(electrophoretic coat) that is applied on the handle and hardened chrome that is applied to the sleeves. Most barbells in this price range will only offer soft chrome, black zinc or black oxide all of which are inferior to

e-coat

and

hardened chrome

. These inferior finishes are thin and wear easily especially soft chrome which is primarily used for decorative items like kitchenware, home decor, or car interior paneling finishes. So why do so many brands use soft chrome? Because it is cheap and shiny.

The Hill Country barbell also beats out ALL OF THE HEX-BOLT barbells for one reason: maintenance and longevity.

Snap-ring construction

barbells require less maintenance and more reliability over hex-bolt barbells that require constant tightening. A good mark of a barbell is the amount of maintenance you don't have to do.

Hardened chrome vs soft chrome

Soft chrome is used for decorative purposes. Kitchen appliances, home decor, interior car paneling trim. It is shiny and smooth offers some corrosion resistance but DOES NOT offer wear resistance. It’s one of the cheapest finishes you can have. This is because it takes much longer to apply “hardened chrome” which is anywhere from 10-100x thicker in application. Hardened chrome is used to finish parts that are functional in nature, like internal machine and engine parts such as valves, pistons, cylinder rings and more. The process for applying chrome is called electroplating and the target material (this case being the barbell) will sit in an acid bath full of chromium solution for a specified time. A electrical current is run through the solution and the metal in such a way that an electrical difference is created between the solution and the barbell. This ends up binding the substrate (chromium) to the barbell. The longer this process goes on the thicker the material. Soft chrome will take minutes where as hard chrome will take hours to complete including the added labor. The hardened chrome finish requires more grinding and finishing of the thicker substance. The chrome is finally cured in an industrial oven. Here again the temperature is higher for hardened chrome due to its additional thickness. Hardened chrome offers better corrosion resistance and due to its thicker nature actually is measured as a harder substance using the Rockwell hardness scale. This translates to finish that has a higher level of wear resistance and durability. This is why hardened chrome is essential for coating barbell sleeves over decorative chrome. Decorative chrome is brittle and will chip almost immediately as you load/unload weight plates repeatedly and if you drop your bar during olympic lifts.

Electrophoretic Paint

Electrophoretic paint is one of the more premium coatings that are used in barbell manufacturing. It offers a high level of corrosion resistance and durability. The only finish to beat its corrosion resistance and durability would be cerakote. It out performs oxide, zinc, and soft chrome finishes in its corrosion resistance. The process involves dipping the barbell in a solution of paint solid particles and amines. An eletrical current is applied to both the solution and the barbell which causes opposite charges to attract. The paint solution then forms a permanent bond with the metal surface of the barbell. After this initial bond is formed the barbell is rinsed and then heated in an industrial oven for 180-200 degrees Celsius. Proof in the pudding E-Coat is one of the most durable finishes on the market available. One way to prove this is to look at publicly available data. A common industry test is called the “Salt Spray Test” in which target objects are subjected to harsh salt water mist for hundreds of hours. RVM Casters out of North Carolina published some data on some samples tested. Important to note is that E-coat out performed standard powder coat, wet paint, and type I and II zinc (similar profile to soft chrome and oxide finishes). In fact E-coat performed at the same or exceeding level as military spec paint. You can ch